Walzwerk Coin Striking Machine for Minting Copper Coins, p. 1 (Story page 49)

Working Principle, Scheme Design, Coin Minting Method, Displacement of Coin Designs and Other Mint Errors

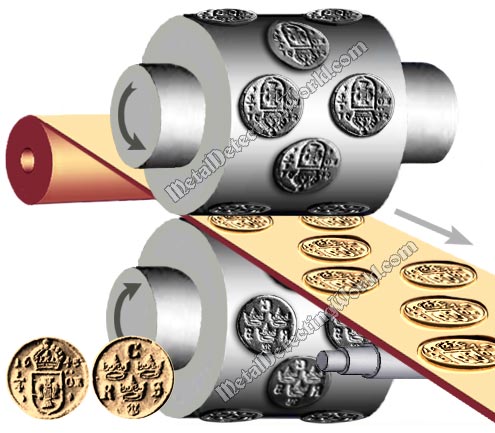

This particular striking defect - displacement of coin designs on either side of a coin (see photo on the right), often occurred during the minting process that was carried out by the coin-striking machine of the "Walzwerk" type. The initial Walzwerk coin machine (also called the Walzwerk Rolling Press) consisted of two heavy iron rollers (cylinders) that were connected by a toothed wheel to provide their synchronous rotation. The machine was powered by horses or water.

Each roller had the same number, four to 19, of dies (either obverse or reverse) engraved on it. The dies of the upper roller were corresponding to the dies of the lower roller. When a strip of the sheet coin-metal was fed through the rollers, the obverse designs were transferred onto one side of the strip, and the reverse designs were imprinted onto another side. Then the strip with the impressed coin designs moved to a punch press ("klippwerk"), where the imprinted spots were punched out; thus, becoming coins. Or the "imprints" were punched out or cut out manually.

Scheme Design of Walzwerk Machine for Minting 1/4 Öre Copper Coins

The corresponding obverse and reverse dies were supposed to be aligned in relation to each other at the point of impressing the sheet metal, but often this was not the case because the rollers were not perfectly synchronized. It was hard to maintain their synchronization because one of the rollers frequently would slow down, jam or stall for a fraction of a second during the process. This caused one of two design imprints to be offset in relation to another on either side of the sheet metal. Outpunching of the nonaligned imprints would follow regardless of their positioning. This resulted in massive production of coins with the displaced obverse or reverse designs.

Mint Errors Related to Walzwerk Coining

There are quite a few mint errors, also called striking errors, that appear on Swedish coins produced by the Walzwerk Coining Press. Mint errors occurred during each stage of the imperfect minting process - from preparing the coin metal sheets to punching the stamped designs out of them. Here is a list of minting defects frequently encountered:

1) Displacement of Coin Design (also called Off-Center Strike) is described above. This defect occurred when the rollers were not synchronized. Off-centering of one or both coin sides appear on many Swedish error coins.

2) Wrong Die Rotation - the coin's reverse is not precisely lined up with the obverse. Die rotation refers to the location of the "top" of the obverse or reverse image when the coin is turned over. For example, if you look at the obverse of the 1/4 Öre coin with a crown right-side up, and then turn the coin over from side to side, all three crowns should be right side up on the reverse. This is called "medal alignment". Another type of die rotation - "Coin Alignment", requires that the coin reverse be right-side up when the coin is turned from top to bottom (all U.S. coins are struck in this die alignment). Some Swedish coins have been found with die rotations ranging from a few degrees off, to a full 180 degrees off. This defect was caused by incorrect placement of dies onto the roller.

3) Clipped Coin defect has two varieties:

• Curved Clipped Coin - the punching mechanism was not aligned properly and cut off the edge of the next coin impression on the copper strip.

• Straighten Clipped Coin - the coin's edge was clipped in a straight line on left or right because the copper strip was made narrower than it was supposed to be before going through the walzwerk coin-stamping press. Coins with this defect are rare because, as a rule, they were recycled. A very rare case of two straight cut-offs, positioned at the right angle to each other, of the coin's edge occurred when the coin design was stamped slightly over the end of the copper strip moving through the walzwerk machine.

4) Cracked Coin Edge - as the copper was not refined properly, the coin metal was too brittle for stamping with high pressure. Or the copper strip was made too thin.

5) Lumps on Coin Surface - the coin bears a raised portion (a "bump") of metal (see picture of coin above - small lump on a circular line at 2 o'clock) which was caused by a defect (dent, gouge or missing detail) in the worn-out die. The dies were manufactured to strike no less than a certain number of coins before being replaced with new ones. To achieve a set number of coins minted by one particular die, mint workers used it as long as possible. But the dies were not of the same quality, so some were getting worn out faster than others. This is why some coins bear lumps of metal on one side and lack of "bumps" on another, or bear defects on both sides.

6) Sharp Details on One Side Only - this is another case of a fresh die being used for stamping the coin's obverse, and an old die was used for the coin's reverse, or vise versa. 7) Die Crack - a raised line of metal in the finished coin. After being subjected to high pressure during the stamping process, a weak die cracked, acquiring a small gap on its surface. If this damaged die continued to be used, the coin metal filled into the crack, thus producing raised line on the coin's surface.

8) Partial Weak Strike - a coin shows a large spot in which all details are illegible. This striking defect could be caused by the uneven pressure applied to the copper strip. Or the copper strip was too thin.

9) Shifted Details - One or two details (crowns, shield, date, etc.) are slightly shifted to the left or right on coin's surface. The mint engravers used a punch (a short iron rod bearing a pattern engraved on its stamping end) to impress individually certain details onto dies. As this was done manually by hammering the punch, the latter could be placed a little bit off its correct position.

10) Double Struck Detail - if a punch was not initially placed correctly on a first strike, the engraver placed the punch correctly and restruck the die.

11) Double Strike - all details are doubled. When a breakage of the copper strip occurred, the workers had to feed the undamaged part of stamped copper strip through rollers backwards in order to save the well stamped coin impressions.

12) Combined Decorations - a coin shows two or three types of decorative details - roses, crosses and squares, instead of just one type. This defect is known to appear on the 1/4 Öre coins minted in 1644-45.

13) Date Overstrike - "4" is placed over number "5" in date. This defect appears on the 1/4 Öre coins minted in 1644.

14) Test Coin - a coin shows design on one side only. This could be a result of testing of a new die. Or the copper strip could exfoliate under the immense pressure of rollers. Such coins are extremely rare.

Despite the large quantities of Swedish copper coins minted by the Walzwerk press during the 17th century, it is most unlikely to come across an ideal copper coin of that period. One or two of the mint errors that I have described above appear on every Swedish copper coin I have dug up. To find an ideal 1/4 Öre coin - a real numismatic treasure, is like to find a pearl!