Rust Removal with Electrolysis - A Detailed Illustrated Tutorial, page 27

5. After-Electrolysis Cleaning of Iron Relics:

Rinsing and Wire-Brushing, What Is Black Coating and How To Clean It Off

1) Rinsing and Wire-Brushing

After the final electrolysis session is completed, switch the power off, pull the artifact out of the electrolytic solution, and treat the artifact following the steps 1 through 3 on page 25.

NOTE: Make sure that the iron object remains WET before it undergoes next treatment.

2) What is the Black Coating?

The cathodic precipitation of insoluble black substance onto iron artifacts that are being electrolytically de-rusted is the major problem encountered with sodium carbonate electrolytes. This black coating is a Sodium Carbonate compound precipitating directly from electrolyte.

This precipitation is more likely to occur at high electric currents, and when tap water containing high levels of carbonate is used to prepare the electrolyte (another good reason for using de-ionized water in the electrolyte!). Black carbonate precipitation is very rare in sodium hydroxide electrolytes.

So if the tap water is used to prepare the electrolyte, the de-rusted artifact will sure be coated with the black carbonate that strongly adheres to the de-rusted surface. It is also hard to wash this black substance off fingers if they get stained with it, so make sure you wear the rubber gloves!

Sticky Black Coating of Sodium Carbonate

The black carbonate is not magnetic, and should not be confused with Black Iron Oxide (also called magnetite - Fe3O4), which is commonly used to add mild corrosion resistance and for appearance of modern handguns, also known as Blackening, Black Passivating, and Gun Bluing. The black carbonate, on the contrary, does not prevent further rusting.

NOTE: The black coating SHOULD NOT be allowed to dry on the de-rusted object, otherwise this coating will be nearly impossible to remove.

How to Clean Black Coating Off Your Derusted Artifact

Removing the black carbonate requires some effort and includes the following:

1) Wire-brushing with a brass-bristled brush that does not scratch the bare iron surface; followed by rinsing.

2) Wire-brushing with a smaller brass brush (shaped like paint brush - found at most welding supply places) that can get into tiny notches and crevices, nooks and crannies; followed by rinsing.

3) Rubbing down with a Scotch scouring pad or Scotchbrite pad - this will take care of some remaining tough spots; followed by a rinse with water.

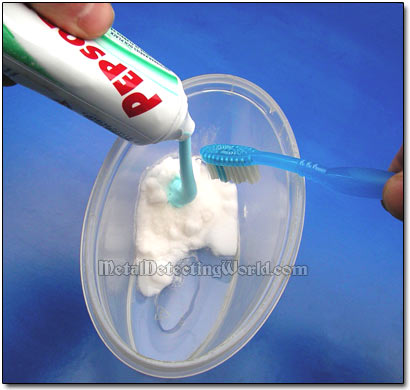

4) Brushing with a nylon brash with use of a mix of baking soda (or washing soda), toothpaste and water. This cleaning mixture will grab the remaining smaller (powder-like) particles of the black carbonate and would not let them stick back to the surface.

It is easy to prepare the cleaning mixture, and you do not have to measure the exact proportions of its components. The goal is NOT to make a mix too liquidy. Use a small plastic container to make enough amount for cleaning one item at a time, or make a large amount if you are not sure how many times you will have to apply the mix.

Making a Mix of Baking Soda, Toothpaste and Water

Mix all ingredients well, so the cleaning mixture is uniformally potent: it is abrasive, penetrating and dirt-catchy.

Mix of Baking Soda, Toothpaste and Water

Cover the entire artifact with the cleaning mixture, and use a medium size regular paint brush to get inside the enclosed areas.

Pouring A Cleaning Mixture onto Derusted Artifact