Minelab E-Trac Field-Test Report: Body Design, page 3

How To Make Vital Modifications to E-Trac's Body To Prolong Its Life

The E-Trac's body design is the same as the Explorer's. So, as I previously did with all my Explorers to make them stay in one piece for long, I made some modifications to the E-Trac's body to prolong its life (see my full article on Reinforcement of Minelab Explorer's Body).

The rubber strap that I wound around the handle made the handle wider, thus allowing for a better grip and excellent maneuverability with firm control on both rapid and slow speed sweeps.

Same Rubber Strap As the One on My E-Trac's Handle

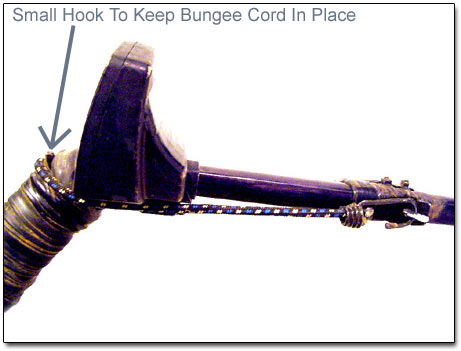

The bungee cord attached to the upper shaft on two sides and running around the handle prevents the upper shaft from swinging loosely sideways and sliding out of the control box camlock. The camlock is the only holding point of the shaft and used to break easily on the early Explorers XS during tough swinging of the search coil through the tall grass.

Same Bungee Cord Fitting is Placed on My E-Trac

This time, the only different modification I made was the replacement of the original arm-rest with the one I made out of plastic pipe. This arm-rest was initially made for Explorer XS back in 2001 and used for five years. I made it narrower and longer than the original to fit my forearm. Because the cable wire with a 1/8" headphone jack was originally attached to the arm-rest, I now simply used the "1/4-inch to 1/8-inch" adapter to plug the wiring into the E-Trac's 1/4" headphone socket.

Home-Made Arm-Rest Attached to My E-Trac

This design takes some strain off the wrist and provides optimum comfort over extended detecting periods. At last, I covered the speaker hole with duct tape to prevent the moisture getting into the control box. Now, the detector was ready for any extreme field conditions!