Search Coils for Metal Detectors, page 3

Types of Search Coils for Metal Detectors: Double-D Wide Scan Search Coils, Advantages and Disadvantages of Design

2) Double D (DD) or 2D Wide Scan

The Double-D coil is characterized by two "D" shaped (transmit and receive) windings aligned back to back (like two opposing letters D) and overlapping. This configuration results in an elliptical shaped (from the toe to the heel of the coil) sensing area which provides a chisel-shaped signal that covers the ground uniformly.

Double-D Coil Disadvantages:

• Pinpointing with DD coils can be challenging and would require a skillful approach (described on page 14) unless you use these coils with a metal detector that has the enhanced or improved Pinpoint feature. Also, the larger a DD coil, the harder it is to pinpoint targets.

• DD coil's inability to detect targets situated close to trees and stone fences if sensing area is inboard by design. This problem was solved with designing an elliptical shaped 2D housing which allows the sensing area be closer to the housing edge. Detection with an elliptical DD coil next to trees and fences became possible, provided the search path is parallel to the obstacle.

Double-D Coil Advantages:

• Double-D Coil is not as affected by heavy ground mineralization as concentric and monoloop coils because the Double-D design "sees" 70% less of the ground mineral effect while covering more ground in one sweep. DD coils are more stable in heavily mineralized and saltwater areas and give you smoother operation in areas where the ground matrix tends to shift.

• DD coil does not require disciplined overlapping and provides a wider scanning of the ground than other coils (as shown by illustration below).

Double-D Search Coils and Their Electromagnetic Field Detection Pattern

Even though the Double-D search coil seems to have more advantages over the concentric coil, its performance, as performance of a search coil of any type, depends on the operating frequency of a metal detector. For example, the gold nugget detectors operate on high frequencies up to 70 kHz to detect the smallest grains of gold. In other words, their operating frequencies cover only one end of the "target spectrum" so to speak. Also the size of the coil plays an important role in this process (see more details on page 5).

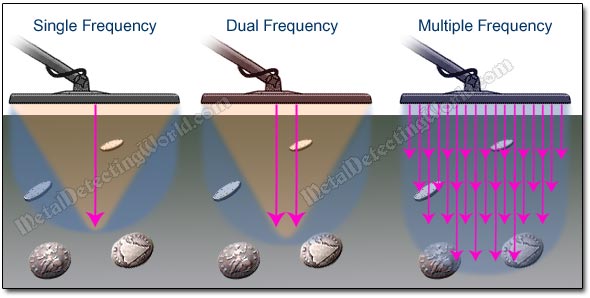

Metal detectors that operate on lower frequencies cover another end of the spectrum. Most of the regular All-Purpose Single-Frequency detectors operate on a frequency that covers the "golden medium" of the "spectrum" but not all of it. The problem with one frequency is that it may work well in one area and often offer only marginal performance when used in another location.

Ground mineralization, trash content and target size all have an effect on how well a detector transmitting a single frequency would operate. The Dual-Frequency metal detectors perform slightly better in terms of target recognition and have a little more depth penetration than single-frequency units. Only the single-frequency metal detectors of the high-operating frequency/high reactivity type, such as the XP GoldMaxx Power and XP Deus, are exceptionally better than not only the dual-frequency detectors but also the multi-frequency machines when it comes to getting the most out of any metal detecting site especially the "searched-out" one!

The machines of the third type - the Multi-Frequency detectors, can provide a full coverage of the "target spectrum," great operational depth range, maximum sensitivity over a wide range of targets and their more accurate identification. Such detectors have either 17 frequencies ranging from 1.5 kHz to 25.5 kHz, or 28 frequencies ranging from 1.5 kHz to 100 kHz. Under extreme conditions, even if a few frequencies of a Multi-Frequency detector can not penetrate the highly mineralized ground, most of the frequencies will complete the job. But, because of their low Recovery Speed (Reactivity), the multi-frequency detectors pass up a lot of the partially masked desirable targets at the iron-infested hunt sites.

This should be considered when deciding which detector and what type of search coils to use for your metal detecting projects.

Detection Patterns of Concentric and 2D Search Coils Operating on Single-, Dual- and Multiple-Frequency