Metal Detectors Minelab Explorers, Safari and E-Trac: Body Modifications

Repositioning a Headphone Socket - Affixing It to Detector's Arm-Rest

The problem with a small 1/8 inch headphone socket of Minelab Explorer XS metal detector may start within the first year of intense metal detecting and transpire itself in a loose position of headphone jack.

During metal detecting process, either the headphone cable puts the pressure on it or the rocks and roots hit the headphone jack when the detector is placed on the rough ground surface (the Explorer XS is not equipped with a detector stand).

After two months of intense use in harsh conditions or without care, the headphone's cable gets multiple internal ruptures, and the repeatable audio "dropouts" become a nuisance.

Short life and replacement of headphones was another major problem of Explorer XS. To eliminate those problems before they would arise, I came up with a simple idea: instead of using the 1/8 inch socket located at the end of handle assembly, I would use the more durable 1/4 inch headphone socket placed on the arm-rest at convenient angle. At that time, I already had a set of Koss headphones with a 1/4 inch jack.

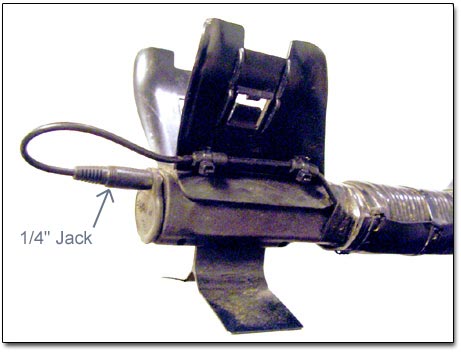

For the Explorer XS metal detector modification, I purchased an adaptor, 1'-long cable with a 1/8 inch headphone jack on one end, a 1/4 inch socket on another, and a volume control in between. I ran the cable around the armrest and secured the headphone socket onto one outer side of the armrest.

For the Explorer II modification, I used a 2'-long extension cable (the shortest one I could find), with 1/4 inch jack on one end and 1/4 inch socket on another. Before I secured the cable with zip ties on the right outside of the armrest, I made sure that I could pull the headphone jack in and out of socket easily. With a tip of a screwdriver heated over the gas stove flame, I made four holes for zip ties in the armrest. Then I had to wind the excess of cable around the handle assembly.

Extension Cable Runs On One Side Of the Arm-rest of Explorer II

On the left outer side of the arm-rest, I made three holes for zip ties and set up the headphone socket on a cushion in the upright position.

It is known that the phone jack must be replaced when metal fatigue occurs and the jack no longer grips the plug's tip tightly after repeated usage. Cheap jacks are more susceptible to that than the jacks that cost just a little more. So make sure you buy the most expensive jack that is made out of better materials and, therefore, will last longer.

Replacing an Original Armrest on Minelab E-Trac with a Home-Made One

To avoid unexpected breaking of the factory-made arm-rest and add more durability to the E-Trac's body, I replaced the original arm-rest with my own piece initially made for Explorer XS back in 2001. To construct it, I used a plastic pipe of 3-7/8 inches (10cm) in diameter. I cut a piece of 5 inches (12.7cm) long and, with use of a few screws, assembled a simple but rigid armrest. Then I ran a cable wire to the receiving 1/4" headphone socket attached to the left side of my new arm-rest as shown on a picture below.

This home-made arm-rest was initially made for Explorer XS, now it is used on E-Trac

I made the arm-rest narrower and longer than the original to fit my forearm. This simple design takes some strain off the wrist and provides optimum comfort over extended detecting periods.

You may want to see my How-To Tutorial - "How To Make Minelab E-Trac's Headphone Operation Wireless"